Scale Stick Measurement

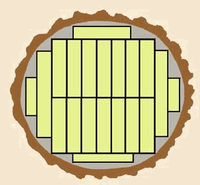

Illustration 1 - Determining

the board-foot volume equates

to how many rectangular

boards can be cut from

the tree.

Standing trees sold for veneer or sawlogs are valued in terms of their board-foot volume, a board foot being a board 1 inch thick by 12 inches wide by 1 foot long. One of the basic tools for measuring the board-foot volume of standing trees is a calibrated tree scale stick. Other names used for this instrument are Cruiser's or Biltmore stick. With the scale stick, the tree's diameter is measured at a point 4 1/2 feet above the ground line and the tree's merchantable height is determined in 16-foot and additional 8-foot log lengths. Knowing these two measurements, the board-foot volume of the tree may be determined using various tree volume tables. Board-foot volumes in these tables will differ because of differences in the way the specific Rules were formulated. Common scales are the International 1/4-inch Rule, the Doyle Rule, and the Scribner Rule. The International 1/4-inch Rule is used to estimate tree volume in the Tree Measurement and Forest Evaluation contest events.

Understanding Board-Foot Volume

Illustration 2 - When a log is cut

up into boards, wood is lost to

sawdust created by the saw

blade (saw kerf - black lines)

and to slabs and edgings

(gray areas).

A tree (or the logs cut from it) is basically a large cylinder. When the tree is cut up into logs, the butt end of a log is larger than the top end. The difference between the top and butt diameter measurements depends on the amount of taper within the log. When an attempt is made to determine the board-foot volume in a tree, ultimately we are attempting to determine how the sawyer at the mill will cut up the logs from the tree into boards to maximize its wood yield (see Illustration 1). Using the various Rules mentioned above is a way of standardizing how many board-feet can be cut from a tree with a given diameter and merchantable height.

Cutting rectangular pieces of wood (boards) from a cylinder (a log) means that there will be some wood that is unusable for lumber. Every time the saw blade passes through the log, solid wood is turned into sawdust. Similarly, there are slabs and edges that will not be used to make boards either (see Illustration 2). This wood is not wasted, however. Sawdust and slabs and edgings are further processed and are often used to make panel-type products such as particleboard. 'Waste' wood can also be burned at the processing plant to generate steam which is, in turn, used to run turbines and generate power for the processing plant. With technology ever increasing, little wood is ever wasted.